Injection moulds

How are injection moulds created?

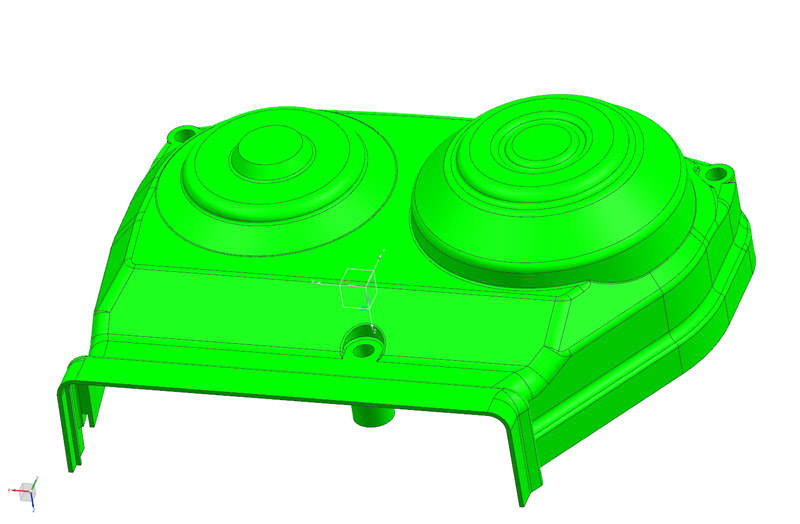

1. Project of the element

- a three-dimensional model of the element (3D model)

- establishing cast alignment

- the choice of materials used to create the element (taking shrinkages into consideration)

- surface finishing (surface quality, texture, structure, colour – the final finish of the product)

- tolerances of the manufactured element

- method of delivery of the element, considering installation requirements

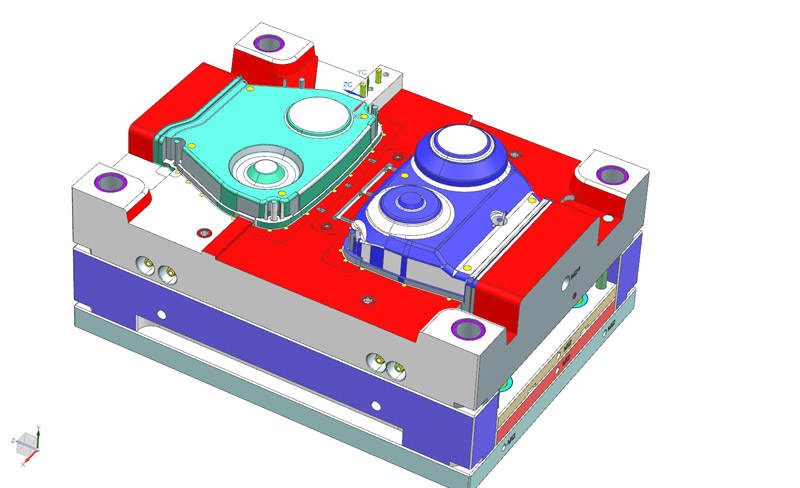

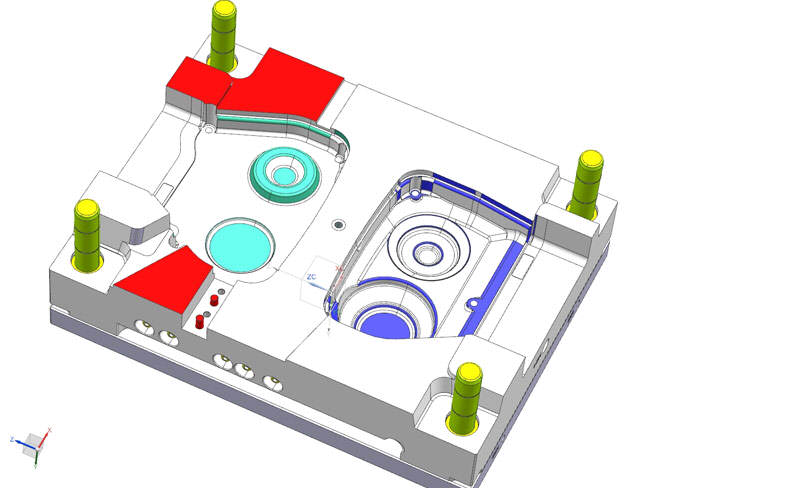

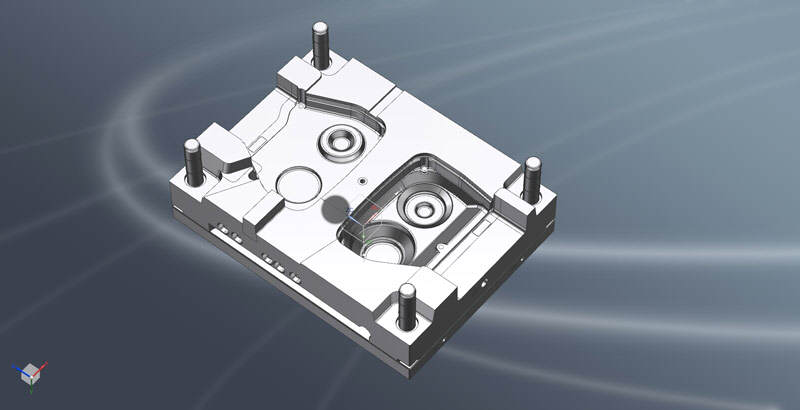

2. Project of the injection mould

- the choice of materials for the mould

- division – outlining the elements of the mould and choosing normalised materials

- considering the type of connection with the moulding machine to be used

- considering cast shrinkages

- checking the mould elements’ collision factor

- preparing CNC programs and the technology used to create the mould

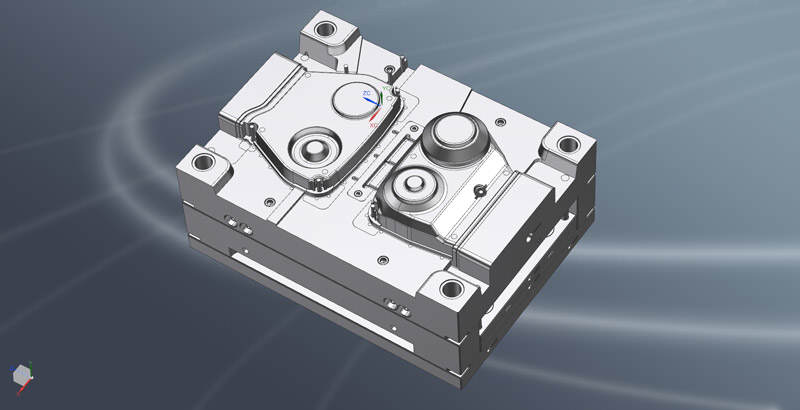

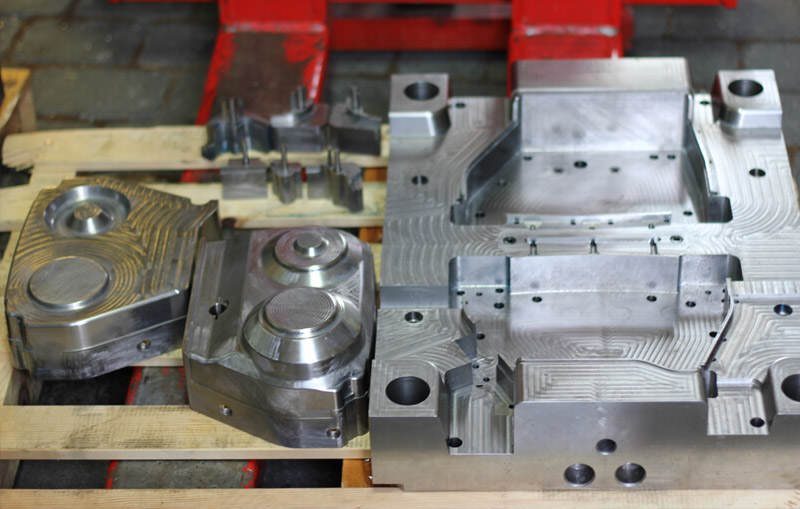

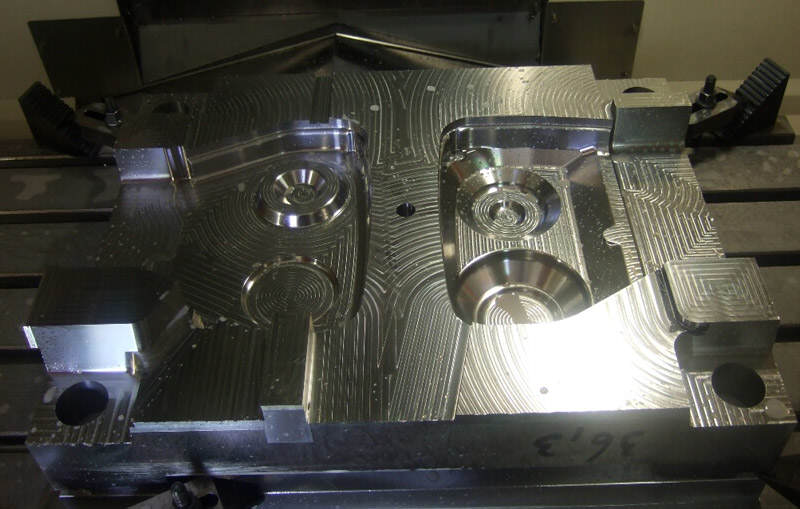

3. Mould creation

- purchase of materials

- manufacture of projected elements – CNC milling

- hardening

- grinding

- EDM processing (die-sink and wire-cut)

- surface cleaning

- threading

- matching

- socket inspection

- tightness inspection

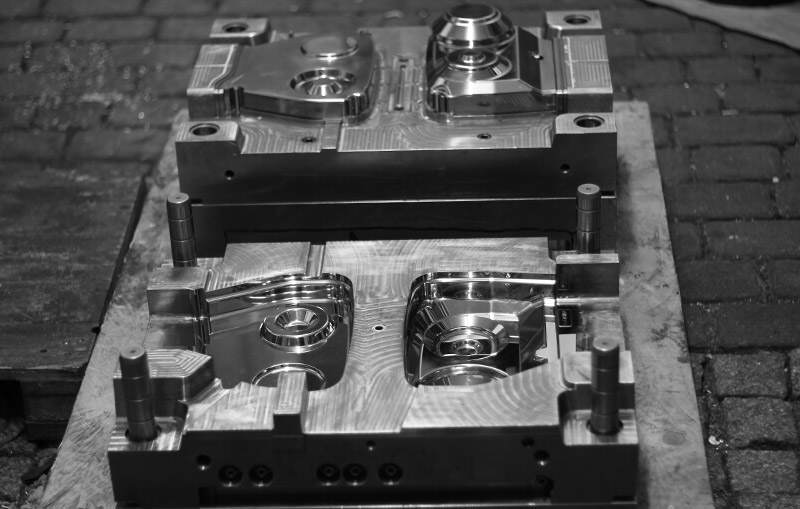

4. First test of the mould

- mould functionality check

- manufacturing first elements

- measurement of the manufactured elements after the initial tests

- quality evaluation

5. Post-test mould adjustment

- removal of flashes

- dimensional adjustment

- surface finishing according to the project specification

6. Final tests

7. Element